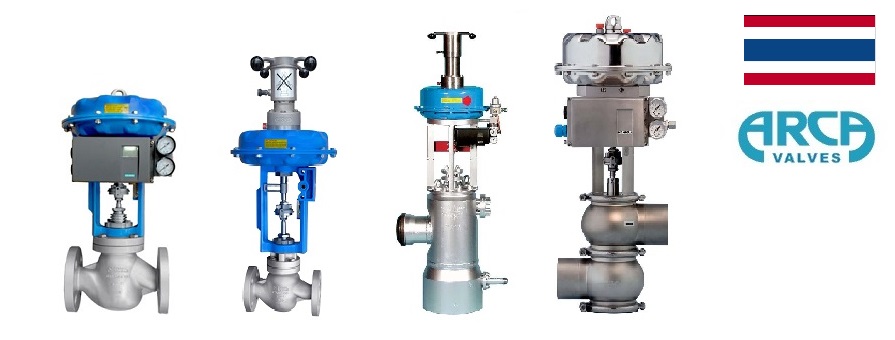

Powerful valve actuator

BIOVENT® control valves are usually combined with pneumatic multi-spring ARCAPAQ actuator type 813. Not only is it cost effective, robust, and explosion proof, but also provides short stroking times and a constant seating force. The actuator is available in different sizes optimised in line with the required actuating force.

Multi-functional positioner

Thanks to the digital ARCAPRO® positioner, BIOVENT® control valves are equipped with a multifunctional interface with the controller or process control system and operate as standard with 4-20 mA. HART, Profibus (PA), and Foundation Fieldbus, for example, are used to establish a digital interface with bi-directional data exchange (including status messages).

Flexible hygienic housing

The stainless steel spherical housing with zero dead space offers the ideal flow conditions. The hygiene-committed design of BIOVENT® control valves is CIP capable and ensures that any residue is drained. This makes the valves easy to clean and prevents damage caused by oxidation as well as media from settling. The housing components are connected by means of stainless steel clamping rings, which facilitates maintenance and allows different housing and connection types to be used.

Hygienic housing and stem seals

EPDM O-rings, which are shaped to a defined size in a form-fit installation space, are used as standard to ensure that the housing components are sealed in line with FDA requirements. The O-ring is pre-tensioned so that it is flush with the wall of the housing and secures the seals. Optimum CIP conditions are ensured. A special combination sealing element with wiper ring is used on the dynamic seal of the valve stems. Purge liquid and/or particles are removed upstream of the sealing element and bearing, thereby preventing them from settling or being crushed between the stem and bearing.

High-precision valve trims

The BIOVENT® control valves are equipped with valve trims specially designed for the prevailing flow conditions in your plant. The shapes of the closure members and valve seats as well as the material from which they are made are optimised in line with your requirements. The replaceable plug and clamped valve seat allow the system to be easily adapted to different operating conditions. Various Kvs values can be selected for each nominal diameter, which means that the valve can be optimised to meet the actual service conditions.

Download