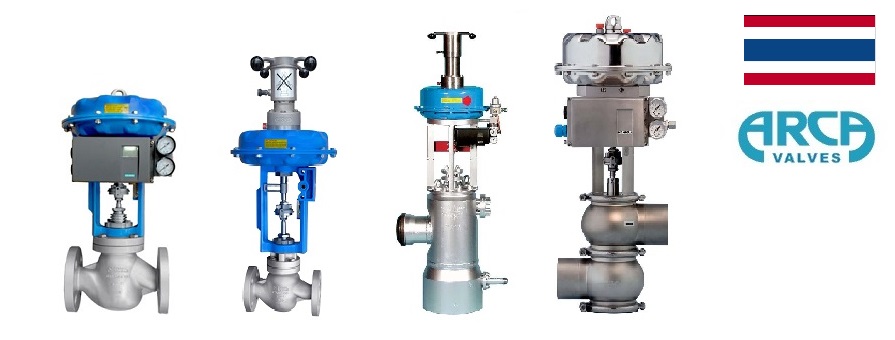

High-performance valve actuator:

Whether you want to use it for control or protective functions, the valve actuator for ARCA’s steam-conditioning valves is designed with your plant in mind. This is made possible by our wide range of pneumatic, electric, and hydraulic actuators. The valve-closing force of all actuators is proportioned according to your requirements.

Multi-functional positioner:

The ARCAPRO® digital positioner provides the steam-conditioning valves with a multi-functional interface to the controller or process control system. It is connected to the actuator directly or using the NAMUR mounting method and ensures that the stroke can always be realized free from backlash for the highest degree of precision. Standardized signals are supported from 4 to 20 mA. HART, Profibus, and Foundation fieldbus standards can also be used to establish a digital interface with bi-directional data exchange (including status messages). This means that the positioner can be parameterised on site as well as remotely via the communication system. Optional accessories such as boosters, limit switches, and solenoid valves are available to customize the valve to suit your individual requirements.

Statically and dynamically leak-proof:

We choose a dynamic stem seal and static bonnet seal in the force bypass that are completely suited to the pressure and temperature range of your application. The surface finish of the stem and the packing material are also factored into this decision. The chambered design normally used for the bonnet seal prevents assembly errors during servicing and maintenance. A self-sealing pinch cap is used for high-pressure applications to ensure that the valve remains sealed regardless of the tightening torque applied to the bonnet screws. These design features also ensure that the valve seat and control cone are not subjected to any lateral forces, thereby minimizing internal leakage as well.

Versatile valve trims:

These are the most crucial functional elements for controlling pressure and temperature. Perforated throttle bodies are designed and manufactured to suit the prevailing flow conditions and the rangeability required. The type of water-injection selected is suited to the temperature of the steam and cooling water. For applications with increased safety regulations, a dirt strainer is inserted at the opening of the steam inlet. This prevents contaminant entry and protects against defects. The patented clamping seat ensures that maintenance is fast, simple, and cost-effective and does not require special tools.

Download